Here we set a fixed structural constraint on the bottom face of the base plate.

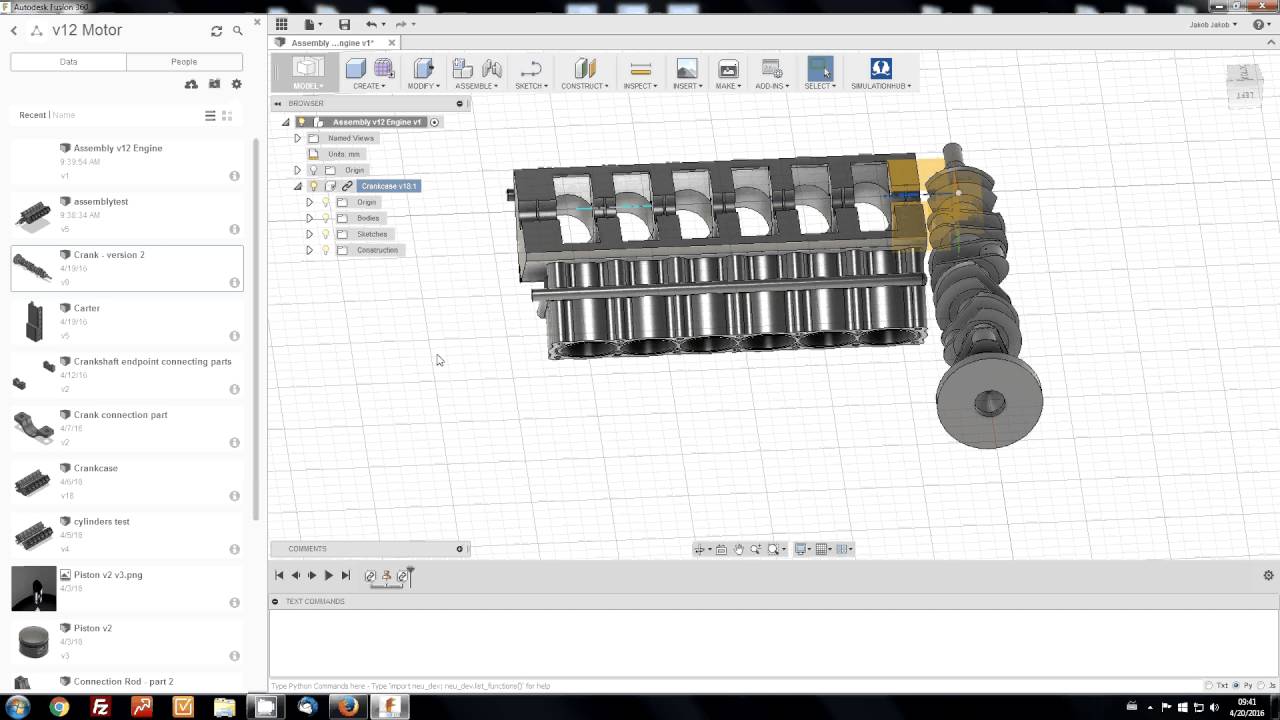

Fusion 360 assembly software#

Having this type of simulation available within your CAD software makes it incredibly easy to go back and forth between tweaking your model and simulating. Make the objects too sturdy and they will be larger, heavier and/or more expensive than they need to be.īy simulating static stress you can strip down unnecessary parts and reinforce weak-points before sending your part to production, making your part strong where you need it to be and at the same time smaller, lighter and cheaper. Make the objects too whimpy and they will break.

When designing mechanical objects you often want them to be just adequately sturdy.

Fusion 360 assembly how to#

In this post we will take a look at how to do basic static stress simulations and talk a bit about why it might be useful. Many are not aware that Fusion 360, a software which actually is free for students, makers and small companies, has these features. Autodesk Fusion 360 has now an easy-to-use simulation module which can be used to simulate static stress, modal frequencies, heat and thermal stress.

0 kommentar(er)

0 kommentar(er)